With the enhancement of environmental consciousness. Nowadays many more environmental regulations limiting or banning the discharge of various types of drilling fluids and associated drill cuttings globally. The drilling contractors started to utilize “zero discharge” or “ship to shore” drilling operations. In these operations, drill cuttings and associated waste fluids are collected on the rig in cutting boxes and then sent back to shore for disposal or treatment prior to disposal. Even when the discharge of drill cuttings offshore is still allowed. There is often now a requirement to collect and transport drill cuttings on the rig for secondary process such as vertical cutting dryer that will reduce the volume of drilling fluids associated with cuttings prior to discharge. In the drilling waste management or some similar works, screw conveyor or auger is a necessary part to convey materials from base ground to a higher position for further treatment.

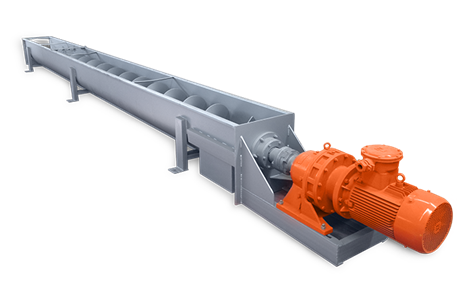

Features and Benefits of Drilling Cuttings Screw Conveyor

1. It has compact structure, small cross section, light weight, good sealing performance, highly efficient transportation, flexible technological layout, with ease of installation, dismantlement, motion and safe operation.

2. It is applicable to transport various kinds of soft materials such as powder, granular and small pieces of materials for example: clay, powder, pulverized coal, cement, sand, grain, small pieces of coal, cobble, cast iron filings, etc.

3. It is not applicable to transport materials that is of high viscosity and is easy to be curdled.

Screw conveyer, commonly known as auger. It has horizontal, inclined and combined form, and it can be used with other transport devices, to accomplish combined transport, separate transport, mixing, blending, dehydration, compounding, discharging and stacking, etc. Brightway Screw Conveyer used in the drilling waste management for the drilling fluids or cuttings transportation. Brightway Screw Conveyor is designed to offer an efficient, low cost, cuttings transport system for offshore and onshore drilling installations. The screw conveyors are manufactured to the highest safety standards and are fitted with protective grating or cover to prevent foreign bodies from entering the conveyor system, and to offer enhanced safety for all personnel.

The waste produced by drilling operations, if not treated properly, will cause great harm to the environment, that is why more and more countries begin to set up regulations to minimize the oil on cuttings, so that the drill cuttings can be reused or discharged.